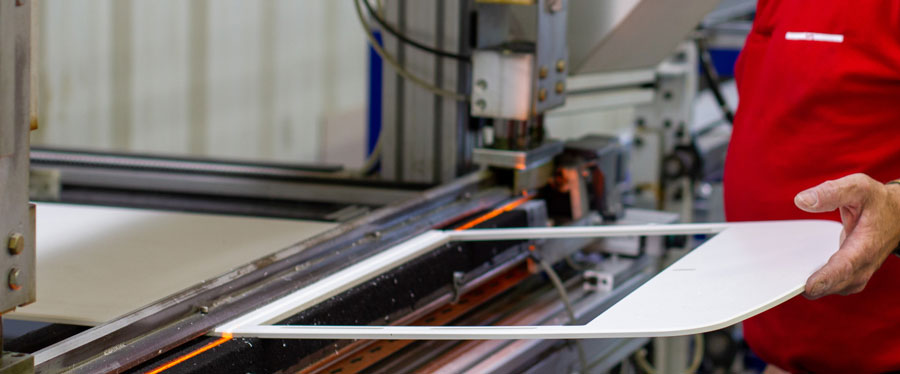

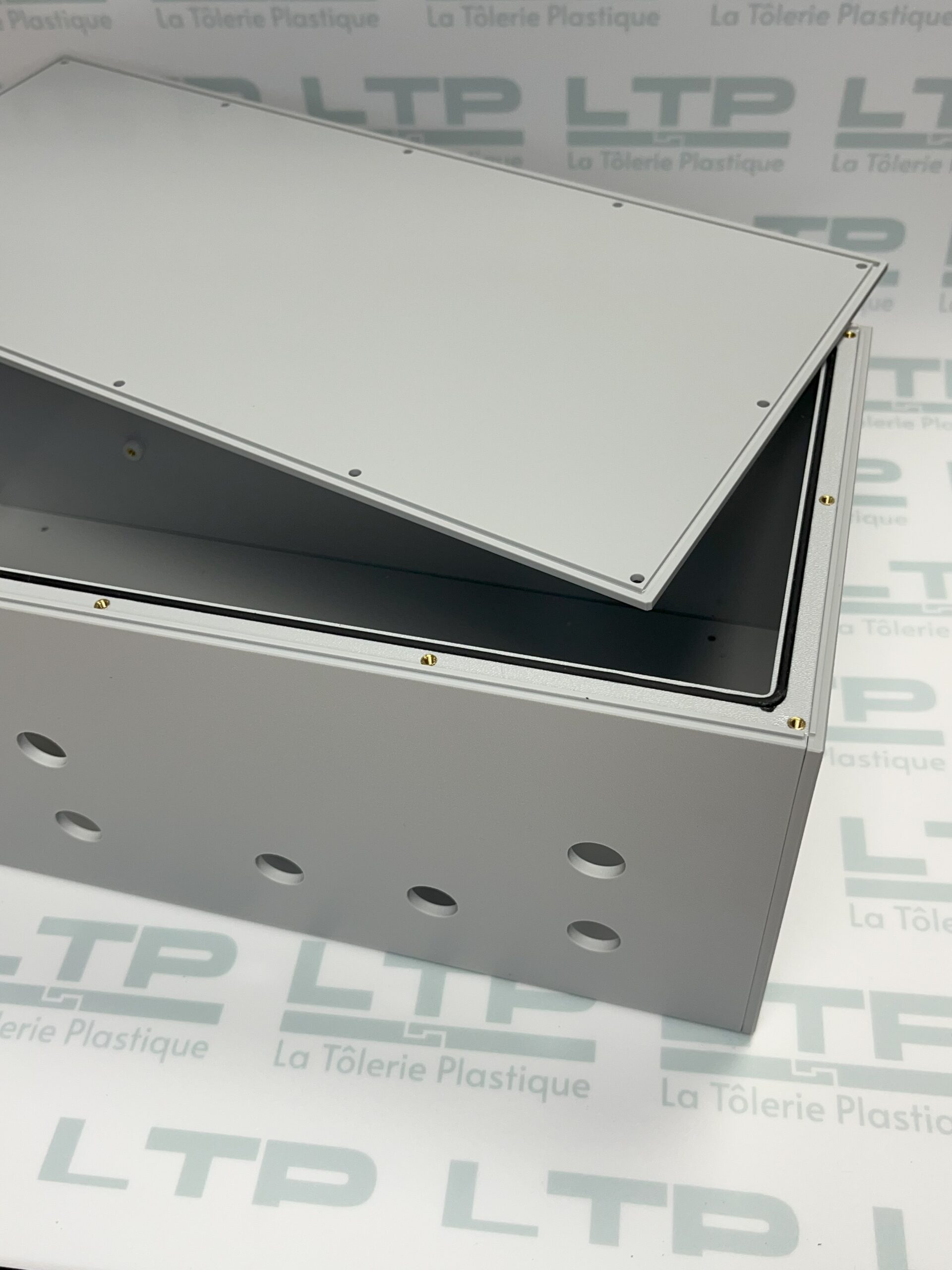

Custom Plastic Enclosures without Tooling Costs: Perfect Protection for Electronics for Battery Packs and Chargers with IP65 Certification

Custom Plastic Enclosures without Tooling Costs: Perfect Protection for Electronics for Battery Packs and Chargers with IP65 Certification